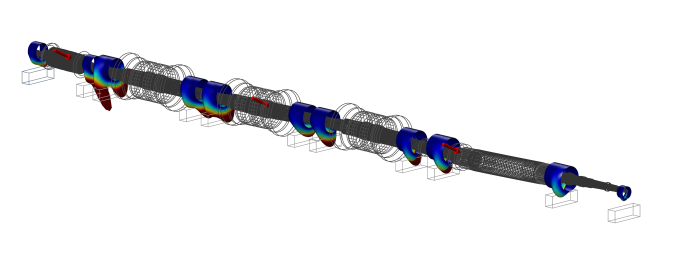

The simulation model of the 70-meter long and 1300-tons shaft of a multistage steam turbine with 11 hydraulic bearings and 290 shaft sections benefits from the integrated Guyan reduction in simulation environment EMD, thus providing attractive computing times. The simulation was done to investigate the rotors bahaviour after turbine blade disruption.

It is, of course, also possible to assess any desired result at every point in time of the full transient simulation. In order to validate the model it is appropriate to use values which are technically easily available such as the shaft movement. However, the strength of the simulation is to make technically inaccessible results – as the pressure distribution in the fluid bearings – available. The possibilities of the script based input facilitate the automated virtual optimization of the system.